-

Measuring principle

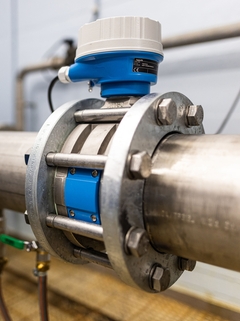

Total solids measurement via microwave transmission

-

Product headline

Total solids measurement for the water and wastewater industry, remote version with up to 4 I/Os. Supports sludge treatment processes (from primary sludge to dewatered sludge).

-

Sensor features

Polished tube – less maintenance due to reduced adhesion.

Fewer process measuring points – multivariable measurement (total solids, temperature, conductivity).

Easy installation – proven sensor construction. -

Transmitter features

Full access to process and diagnostic information –numerous, freely combinable I/Os.

Onboard load calculation – less effort needed in programming.

Integrated verification – Heartbeat Technology. -

Nominal diameter range

DN 50 to 300

-

Installation

Inline installation

-

Material

Measuring tube:

Stainless steel 1.4408 according to DIN EN 10213, CF3M according to ASME A351)

Temperature sensor:

1.4435 (316L) -

Measurement range

0 to 500 g/l (0 to 31 lb/ft3), 0 to 50%

-

Connection

Wafer

-

Ingress protection

IP66/67, Type 4X enclosure

-

Display/Operation

4-line backlit display with touch control (operation from outside)

Configuration via local display and operating tools possible -

Output / communication

4-20mA HART, Modbus RS485

-

Power supply

AC 100 to 240 V / AC/DC 24 V

-

Product safety

CE Marking, UKCA Marking

-

Hazardous area approvals

ATEX, IECEx, CSA C/US

-

Material certificates

3.1 material

-

Metrological approvals and certificates

Heartbeat Technology complies with the requirements for measurement traceability according to ISO 9001:2015 – Section 7.1.5.2 a (TÜV SÜD attestation)

Field of application

The measuring device Teqwave MW 500 enhances sludge treatment in wastewater treatment plants through real-time total solids measurement using microwave transmission. This allows quicker, more efficient process optimization and fewer lab measurements. Continuous data availability improves solid-liquid separation, boosts operational safety, and enables swift response to process changes. Typical applications in sludge treatment include clarification, digestion, and dewatering.

The remote transmitter version Proline 500 allows for maximum installation flexibility in challenging environments. Equipped with a built-in web server and optional integrated WLAN, it simplifies operation and provides additional process and device information.

Benefits

Reliable, real-time measuring performance – permanent in-line measurement with excellent repeatabilityLess maintenance – polished measuring tube reduces build-up formation and extends cleaning intervalsReduced effort in programming – onboard load rate calculation available in combination with a flowmeterFewer process measuring points – multivariable measurement (total solids, temperature, conductivity)Easy installation – innovative sensor construction and state-of-the-art technology with web server (optional WLAN)Full access to process and diagnostic information – numerous freely combinable I/Os availableIntegrated verification – Heartbeat Technology enables documented device functionality without process interruption