-

Measuring principle

Vibration Liquids

-

Characteristic / Application

Compact vibronic device for high pressure and high temperature applications,

Optional extension tube up to 6 m (19.7 ft),

Modular housing concept,

Wide range of certificates -

Specialities

Heartbeat Technology,

Bluetooth® Operation and maintenance SmartBlue App,

LED Module,

RFID TAG for easy identification,

Second line of defense,

Temperature spacer for high process temperature,

Plug and play functionalities -

Supply / Communication

19…253V AC / 2-wire,

10…55V / DC-PNP 3-wire,

9…20V DC with relay DPDT,

19…253V AC or 19…55V DC with relay DPDT,

2-wire NAMUR,

2-wire PFM,

4-20mA HART -

Ambient temperature

-60 °C…+70 °C

(-76 °F…+158 °F) -

Process temperature

-60 °C…+280 °C

(-76 °F…+536 °F) -

Process pressure / max. overpressure limit

Vacuum…100 bar

Vacuum…1450 psi -

Min. density of medium

0.5 g/cm³

(0.4 g/cm³ optional) -

Main wetted parts

316L

Alloy -

Process connection

Threads:

3/4″, 1″

Flanges:

DN25…DN100

ASME 1″…4″

JIS 50A -

Sensor length

up to 6 m (19.7 ft)

-

Communication

2-wire direct load

HART

DC-PNP 3-wire

Relays

NAMUR

PFM

Bluetooth® wireless technology -

Certificates / Approvals

ATEX, IEC Ex, NEPSI, EAC Ex, KC, JPN Ex, INMETRO, UK Ex

-

Safety approvals

Overfill protection WHG

SIL2/ SIL 3 according to IEC 61508 -

Design approvals

EN 10204-3.1

NACE MR0175, MR0103

ASME B31.3 Process Piping

AD2000

CRN -

Marine approval

ABS/ LR/ BV/ DNV

-

Options

Ambient temperature down to -60 °C (-76 °F),

Heavy duty stainless steel housing,

Coating PFA (conductive) -

Components

FTL325P Interface PFM

FTL325N Interface NAMUR

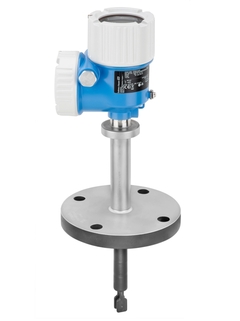

Field of application

Liquiphant FTL64 has a strong focus on high temperature applications and simplicity with easy proof testing, reliability and safety (SIL) with compliance to IEC 61508, API 2350 and WHG. The vibronic device is determined for a safe and active measuring technology in applications with high temperatures and want a reliable and proven point level detection for tank overfill protection and pump dry run protection. The FTL64 is easy to use, has a digital connection and gives a real-time data at hand.

Point level switch with extension tube for pumpable liquidsProcess temperature: -60 °C to +280°C (PFA coated: up to 230°C) Process pressure: -1 to +100bar (PFA coated: up to 40bar) Ambient temperature: -60 to +70°C Viscosity up to 10,000mm2/s (cSt) Optional PFA coating for aggressive media Process connections: threads, flanges and hygienic process connection (Tri-Clamp)International explosion protection certificates, overfill protection WHG, SIL, marine approvals

Benefits

Universal measuring principle for limit detection – proven vibronic technology Developed according IEC 61508 for highest safety – SIL2/3 applications (3rd party approved)Periodic proof testing is quickly and simple organized with guided wizards via the SmartBlue-App or via a test button or magnetic pin from outside. Via digital communication you can initiate the device for a fast and easy testing of the safety loop.Heartbeat Technology allows safe, continuous diagnostics and a simple verification, without process interruptionCentralized asset management with easy online access to all device information thanks to digital communication Second line of defense to protect the environment